In an era of booming technology, electric vehicles are gradually becoming an inevitable trend of the future. To operate smoothly and efficiently, electric vehicles need a strong and stable electrical system. And the key role in this system belongs to Busbar. So what is Busbar and what is its application in electric vehicles? Let’s explore the details in this article!

1. Busbar – Definition, structure and operating principle

A busbar, or busbar, is a conductive metal bar used to distribute electricity in electrical systems. It is usually made of copper or aluminum due to its good electrical conductivity and high durability. Busbars can be designed in a variety of shapes and sizes to suit specific applications.

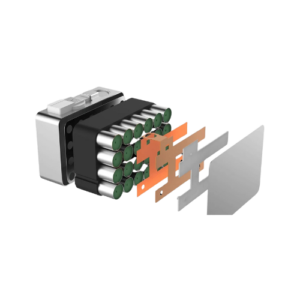

Busbar’s structure includes:

- Metal core: Is the main conductive part, usually made of copper or aluminum. The metal core can be made in solid bar, perforated bar or mesh form to optimize electrical conductivity and heat dissipation.

- Insulating layer: Covers the metal core to protect users from the risk of electric shock and prevent short circuits. Common insulating materials include plastic, rubber or mica. The insulation needs to be able to withstand high voltages, high temperatures and harsh environments.

- Accessories: Includes connectors, clamps and brackets to connect and secure the Busbar in place. Accessories need to have good conductivity, high load capacity and ensure safety during operation.

Busbar’s operating principle:

Busbar operates on the principle of electrical conduction. When current is passed into the Busbar, it moves along the metal core and is distributed to other parts of the electrical system through the connectors. The insulating layer will protect users and other parts from the risk of electric shock and ensure safety during operation.

2. Outstanding advantages of Busbar in electric vehicles

Busbar is widely used in electric vehicles because of many outstanding advantages, including:

- Good electrical conductivity: Busbar has high electrical conductivity, helping to minimize power loss during transmission. Thanks to this, electric vehicles can operate more efficiently, save energy and increase travel distance.

- High efficiency: Busbar contributes to improving the performance of electric vehicles thanks to its ability to distribute power stably and evenly. This helps ensure the engine runs smoothly, the electronics operate correctly and enhances the user experience.

- Save space: Busbar has a compact design, helping to save installation space in electric vehicles. Thanks to this, manufacturers can optimize vehicle size and increase space for other components such as batteries, engines or passenger compartments.

- Light weight: Busbar is made from lightweight materials such as aluminum or copper, contributing to reducing the overall weight of the electric vehicle. This helps the vehicle move more flexibly, save energy and improve operating performance.

- Reasonable cost: Busbar is cheaper than other conductive solutions, helping to optimize the cost of electric vehicle production. Thanks to this, electric vehicles become more affordable for consumers, promoting the development of the electric vehicle market.

- High durability: Busbar is able to withstand vibrations, impacts and extreme temperatures, ensuring stable operation in the operating environment of electric vehicles. Thanks to that, electric vehicles can operate durably for a long time without needing regular maintenance.

3. Diverse applications of Busbar in electric vehicles

Busbar plays an important role in many parts of electric vehicles, including:

- Battery system: Busbar connects battery cells together to form a battery pack, helping to distribute power from the battery to other parts of the vehicle. The busbar in the battery system needs to have high electrical conductivity, withstand large currents and ensure safety during the charging/discharging process.

- Power distribution: Busbar is a key part in distributing power from the battery pack to other parts of the electric vehicle. Busbar is designed with many branches and suitable sizes to meet the diverse power needs of different parts such as motors, controllers, lighting systems, entertainment systems,…

- Engine system: Busbar provides power to the electric motor, helping the vehicle move. Busbars in the engine system need to have high electrical conductivity, withstand large currents and have high durability to ensure stable operation of the engine..

- Control system: Busbar provides power for the vehicle’s electronic control system, including lighting system, air conditioning system and entertainment system. Busbars in the control system need to have good electrical conductivity, high safety and ensure accuracy in the process of transmitting control signals.

- Charging system: Busbar connects the battery charger to the vehicle’s electrical system, helping to transmit electricity from the charging source to the battery. The busbar in the charging system needs to have high electrical conductivity, withstand large currents and have high safety to ensure safety during the battery charging process.

In addition, Busbar is also used in many other parts of electric vehicles such as regenerative braking systems, battery monitoring systems and four-wheel drive systems.

4. The future development of Busbar in electric vehicles

With outstanding advantages, Busbar is predicted to continue to play an important role in electric vehicles in the future. Researchers are constantly developing new types of Busbars with higher performance, lighter weight and cheaper prices, contributing to the development of the electric vehicle industry.

Some of the development trends of Busbar in electric vehicles include:

- Developing Busbars with higher efficiency: Researchers are focusing on developing Busbars with higher electrical conductivity, helping to minimize power loss and improve the performance of electric vehicles.

- Reduce Busbar weight: Using lighter materials such as aluminum or carbon fiber composite will help reduce Busbar weight, contributing to reducing the overall weight of electric vehicles and improving operating performance.

- Increase the durability of the Busbar: Researchers are developing types of Busbars that can better withstand vibration, impact and extreme temperatures, helping to ensure stable and durable operation of electric vehicles over time. long time.

- Developing Smart Busbars: Smart Busbars are integrated with sensors and microprocessors that can monitor current, temperature and other parameters in the electrical system, helping to detect problems early and Protect the electrical system from damage.

5. Conclude

Busbar is an essential component in electric vehicles, playing an important role in distributing electricity and ensuring efficient operation of the vehicle. With outstanding advantages and huge development potential, Busbar will continue to be the top choice for electric vehicle manufacturers in the future.

Why choose SHOGO Viet Nam?

1. Quality Commitment: SHOGO Viet Nam.,JSC is the No.1 Busbar and Cable manufacturer in Viet Nam for the new energy industry. We are committed to providing our customers with products of the highest quality standards. All raw materials are inspected for quality before production, and 100% of products are thoroughly inspected before delivery. SHOGO Viet Nam holds prestigious certificates: IATF16949-2016, ISO 9001-2015, ISO 14001-2015, ISO/IEC 17025-2017,…

2. Competitive Pricing: With a team of experienced engineers who have participated in many electric vehicle production projects, SHOGO Viet Nam can provide product consulting to help customers optimize production costs and improve product quality. With a geographical location that is convenient for trading, along with modern machinery and technology, SHOGO Viet Nam can provide products at the most competitive prices on the market.

3. Dedicated Service: With a team of experienced employees, large production capacity and reasonable supply, SHOGO Viet Nam always ensures on-time delivery for customers. Support customers in all projects, quickly handle arising problems.

You can refer to some of our Busbar products on the page PRODUCTS

To receive FREE CONSULTATION on our products, Busbar design and manufacturing services, please CONTACT

Email: info@shogovn.com / info@shogobusbar.com

Whatsapp / Wechat / Zalo : +84 989538022 / +84 393929885