1. What is a Laminated Busbar?

Laminated Busbar is a type of electrical conductor made of many thin layers of metal pressed together. These metal layers are usually made of copper, aluminum or their alloys.

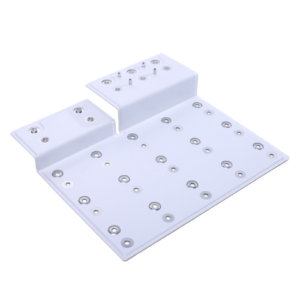

2. Structure of Laminated Busbar

The basic structure of a Laminated Busbar includes:

- Core layer: The core layer is the main part of the busbar, made of many thin layers of metal pressed together. The core layer can be made of copper, aluminum or an alloy of these two metals. The thickness and number of metal layers in the core layer will depend on the current and voltage requirements of the electrical system.

- Insulation layer: Insulation layer is used to isolate the metal layers in the busbar from each other, preventing short circuits. The insulation can be made of a variety of materials, such as plastic, mica, or insulating paper.

- Shell: The shell protects the busbar from environmental factors such as dirt, moisture and chemicals. The housing can be made of metal, plastic or composite materials.

3. Classification of Laminated Busbar

There are two main types of laminated busbars:

3.1. Insulated Laminated Busbar:

This type of busbar is the most commonly used and consists of many electrical conductors insulated from each other with insulating material such as plastic or paper. The insulating material helps prevent short circuits between electrical conductors and protects the operator from electric shock.

3.2. Uninsulated Laminated Busbar:

This type of busbar does not use insulating material and instead relies on air to provide insulation between the conductors. Uninsulated busbars are often used in applications where space is limited or where better heat dissipation is required.

Additionally, Laminated Busbars can be classified according to the arrangement of the conductive bars. The most common types of arrangements include:

- Flat Laminated Busbar: This type of busbar has electrical conductors arranged flat next to each other. Flat busbars are often used in applications where space is limited.

- Cascading Laminated Busbar: This type of busbar has electrical conductors arranged in multiple layers. Cascading busbars are commonly used in high current applications.

- Spiral Laminated Busbar: This type of busbar has conductive bars arranged in a spiral shape. Spiral busbars are commonly used in high frequency applications.

4. Advantage of Laminated Busbar

Laminated busbars offer many advantages over traditional busbars, including:

Higher performance:

- Reduced power loss: Due to the multi-layer structure that reduces resistance and inductance, Laminated Busbar transmit power more efficiently, minimizing power loss.

- Increased heat dissipation efficiency: The larger surface area of the Laminated Busbar provides better heat dissipation, which reduces the risk of overheating and increases longevity.

Compact size:

- Flexible design: Laminated Busbar can be designed with many different shapes and sizes, suitable for many installation spaces.

- Space saving: The compact size of the Laminated Busbar saves installation space, especially important in applications with limited space.

High reliability:

- High load capacity: Laminated Busbar have a higher load capacity than traditional busbars, helping to meet the increasing demand for power.

- Long lifespan: Laminated busbars are less susceptible to corrosion and damage than traditional busbars, thus have a longer lifespan.

Easy to install:

- Simple connection: Laminated busbars can be easily connected by welding, clamping or screw methods.

- Simple maintenance: The simple design of the Laminated Busbar makes maintenance easier.

In addition, Laminated Busbar also have a number of other advantages such as better resistance to electromagnetic interference, better ability to adapt to harsh environments, and are more environmentally friendly.

5. Application of Laminated Busbar

Electric Car

The multi-layer busbar integrates a number of components such as fuses, connectors, etc. High integration and can be applied to mass production of automotive automation

The infrastructure

Multi-layer busbars are applied in communication infrastructure, telecommunications switching systems, large-scale telecommunications switching systems, ground transportation,…

Railway traffic

Multi-layer busbars are used in railway traffic

Wind and photovoltaics

Multi-layer busbars are used in

6. Some notes when using Laminated Busbar

Selection and installation:

- Size: Choose a busbar with a size appropriate to the current and capacity used.

- Material: Priority is given to using copper or aluminum bus bars with high conductivity and good load-bearing capacity.

- Installation method: Install the busbar according to the manufacturer’s instructions, ensuring a firm and safe connection.

- Installation location: Avoid installing the busbar in damp, high temperature or corrosive chemical locations.

Operation and maintenance:

- Periodic inspection: Regularly check the busbar for signs of damage, cracks, or corrosion.

- Cleaning: Clean the busbar with a soft cloth and suitable cleaning solution.

- Maintenance: Perform routine maintenance as recommended by the manufacturer.

Safe:

- Be careful when handling: When working with busbars, it is necessary to comply with electrical safety measures such as wearing insulating gloves and using appropriate tools.

- Avoid direct contact: Direct contact with the busbar is not allowed when energized.

- Disconnect the power source: When repair or maintenance is needed on the busbar, the power source must be completely disconnected.

In addition, the following points should be noted:

- Use accessories suitable for the type of busbar being used.

- Connect the busbar to other electrical equipment using specialized connectors.

- Install a safe grounding system for the busbar.

Complying with the above notes will help ensure safety and prolong the life of Laminated Busbar.

7. Conclusion

Laminated busbars are an efficient and flexible electrical conduction solution for many different industries. With many advantages such as high load capacity, high durability, good electrical conductivity and easy installation, Laminated Busbar are being used more and more widely.

Why choose SHOGO Viet Nam?

1. Quality Commitment: SHOGO Viet Nam.,JSC is the No.1 Busbar and Cable manufacturer in Viet Nam for the new energy industry. We are committed to providing our customers with products of the highest quality standards. All raw materials are inspected for quality before production, and 100% of products are thoroughly inspected before delivery. SHOGO Viet Nam holds prestigious certificates: IATF16949-2016, ISO 9001-2015, ISO 14001-2015, ISO/IEC 17025-2017,…

2. Competitive Pricing: With a team of experienced engineers who have participated in many electric vehicle production projects, SHOGO Viet Nam can provide product consulting to help customers optimize production costs and improve product quality. With a geographical location that is convenient for trading, along with modern machinery and technology, SHOGO Viet Nam can provide products at the most competitive prices on the market.

3. Dedicated Service: With a team of experienced employees, large production capacity and reasonable supply, SHOGO Viet Nam always ensures on-time delivery for customers. Support customers in all projects, quickly handle arising problems.

You can refer to some of our Busbar products on the page PRODUCTS

To receive FREE CONSULTATION on our products, Busbar design and manufacturing services, please CONTACT

Email: info@shogovn.com / info@shogobusbar.com

Whatsapp / Wechat / Zalo : +84 989538022 / +84 393929885