1. What is Aluminum Busbar?

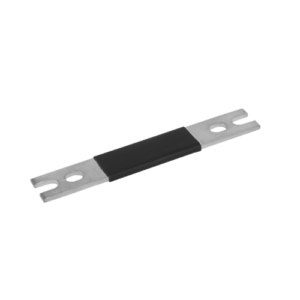

Aluminum Busbars are electrical equipment used to conduct large currents in electrical systems. It is made from aluminum, a metal that is lightweight and conducts electricity well, has high load-bearing capacity and is reasonably priced. Aluminum busbars are widely used in many different industries.

2. Structure of Aluminum Busbar

2.1. Aluminum core:

This is the main part of Aluminum Busbar, made from high conductivity aluminum, usually AA6061 or AA6063 aluminum. The aluminum core can be solid or tubular, depending on strength and heat dissipation requirements.

2.2. Insulation:

The insulating layer wraps around the aluminum core to separate it from other conductive parts and protect the user from the risk of electric shock. The most common insulation material for Aluminum Busbar is PVC, XLPE or EPR. The thickness of the insulating layer depends on the voltage of the electrical system.

2.3. Protective shell:

The protective cover is applied over the insulating layer to protect Aluminum Busbar from environmental factors such as dirt, moisture, chemicals and UV rays. The most common protective cover material is galvanized or plastic,…

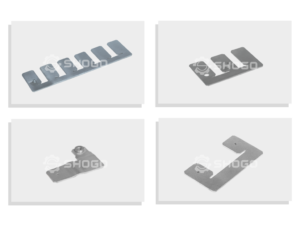

2.4. Accessory:

Aluminum Busbar can also include some other accessories such as connecting bars, bending bars, branching bars, etc. to connect to other electrical devices in the system.

In addition, some Aluminum Busbars can also be integrated with other special features such as fire resistance, explosion protection or impact resistance.

2.5. Factors affecting the structure of Aluminum Busbar

The structure of Aluminum Busbar can be affected by some of the following factors:

- System voltage: The higher the system voltage, the greater the thickness of the insulation layer must be.

- Current: The larger the current, the larger the size of the aluminum core must be.

- Environment: The operating environment of the aluminum busbar can influence the choice of material for the protective cover.

- Aesthetic requirements: Aluminum Busbar can be designed with many different shapes and colors to suit the aesthetic requirements of the project.

3. Classification of Aluminum Busbar

Aluminum Busbar is classified into two main types:

- Flexible Aluminum Busbar: This type can be bent and flexible, suitable for applications that need to move or change position.

- Solid Aluminum Busbar: This type has high hardness and high load capacity, suitable for fixed applications.

4. Advantages of Aluminum Busbar

- Light weight: Aluminum is 67% lighter than copper. This helps reduce the overall weight of the electrical system, which is especially important for overhead or mobile applications.

- Lower cost: Aluminum is significantly cheaper than copper. This can result in significant project cost savings, especially for large electrical systems.

- High electrical conductivity: Aluminum has high electrical conductivity, only slightly lower than copper. This means that aluminum busbars can transmit power efficiently with little power loss.

- High corrosion resistance: Aluminum creates a protective oxide layer that helps prevent corrosion. This makes aluminum busbars ideal for applications outdoors or in harsh environments.

- Easy to install: Aluminum busbars are easier to install than copper busbars. They can be bent and cut into different shapes to fit any layout.

- Sustainability: Aluminum is a highly recyclable material. This makes aluminum busbars a more environmentally friendly choice than copper busbars.

- Good power distribution: Aluminum bus bars can distribute power more evenly than copper bus bars. This can help improve electrical system performance and reduce power loss.

- Less Electromagnetic Interference: Aluminum busbars generate less electromagnetic interference (EMI) than copper busbars. This can help improve electrical system reliability and minimize interference with other electronic devices.

Defect:

- Lower mechanical strength: Aluminum has lower mechanical strength than copper. This means that aluminum busbars can be bent or damaged more easily than copper busbars.

- Lower solderability: Aluminum is more difficult to weld than copper. This can make aluminum busbar connections more complicated.

Overall, aluminum busbars offer many advantages over copper busbars, including lighter weight, lower cost, high corrosion resistance, and ease of installation. However, aluminum busbars also have some disadvantages, such as lower mechanical strength and lower weldability. Therefore, choosing which type of busbar is suitable for a particular application will depend on project-specific factors.

In addition, it should be noted that aluminum busbars come in many different types, each with its own advantages and disadvantages. Therefore, it is important to choose the right type of aluminum busbar for the specific needs of the application.

5. Application of Aluminum Busbar

Aluminum Busbar is used in a variety of applications, including:

- Substation: Aluminum Busbar is used to transmit power in the substation.

- Power Plant: Aluminum Busbar is used for power transmission in power plant.

- Buildings: Aluminum Busbar is used for power distribution in buildings.

- Boats: Aluminum Busbar is used to supply power to equipment on boats.

- Electric Vehicles: Aluminum Busbar is used to supply power to the motor and other electrical devices in electric vehicles.

6. Some notes when using Aluminum Busbar

When using Aluminum Busbar, the following points should be noted:

- Choose the right type of Aluminum Busbar for the right application.

- Make sure the size and shape of the Aluminum Busbar matches the electrical system.

- Install Aluminum Busbar properly to ensure safety and operational efficiency.

- Store Aluminum Busbar in a cool, dry place and away from corrosive chemicals.

7. Conclusion

Aluminum Busbar is an important electrical device with many advantages and wide applications. With light weight, good electrical conductivity, high corrosion resistance and reasonable price, Aluminum Busbar is the optimal choice for many different electrical systems.

Why choose SHOGO Viet Nam?

1. Quality Commitment: SHOGO Viet Nam.,JSC is the No. 1 Busbar and Cable manufacturer in Viet Nam for the new energy industry. We are committed to providing our customers with products of the highest quality standards. All raw materials are inspected for quality before production, and 100% of products are thoroughly inspected before delivery. SHOGO Viet Nam holds prestigious certificates: IATF16949-2016, ISO 9001-2015, ISO 14001-2015, ISO/IEC 17025-2017,…

2. Competitive Pricing: With a team of experienced engineers who have participated in many electric vehicle production projects, SHOGO Viet Nam can provide product consulting to help customers optimize production costs and improve product quality. With a geographical location that is convenient for trading, along with modern machinery and technology, SHOGO Viet Nam can provide products at the most competitive prices on the market.

3. Dedicated Service: With a team of experienced employees, large production capacity and reasonable supply, SHOGO Viet Nam always ensures on-time delivery for customers. Support customers in all projects, quickly handle arising problems.

You can refer to some of our Busbar products on the page “PRODUCTS“.

To receive FREE CONSULTATION on our products, Busbar design and manufacturing services, please CONTACT

Email: info@shogovn.com / info@shogobusbar.com

Whatsapp / Wechat / Zalo : +84 989538022/ +84 393929885