Solid Busbar plays an extremely important role as a “blood vessel” that guides the flow of power from the supply source to different loads. So what is Solid Busbar? What is its application? This article will provide you with detailed information about this special type of electrical conductor.

1. What is Solid Busbar?

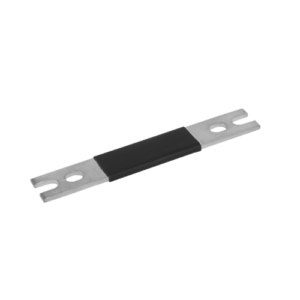

Solid Busbar, also known as solid busbar, is a metal bar used to conduct electricity in electrical systems. It is usually made of copper or aluminum, and comes in solid or hollow tubes.

2. Structure of Solid Busbar

2.1. Core

The core is the main part of the Solid Busbar, made from highly conductive metal, usually copper or aluminum. The core can be hollow or solid, depending on the needs and application.

- Hollow tube core: This type of core is lighter in weight and saves more material, but has a lower load-bearing capacity than a solid core.

- Solid core: This type of core has a higher load capacity and better stiffness, but weighs more and consumes more material.

2.2. Cover

The sheath, also known as the insulating layer, is the layer that covers the core of the Solid Busbar. The casing can be made from many different materials such as PVC, XLPE, EPDM, etc. The main purpose of the casing is to insulate the core, prevent electrical leakage and protect the core from external factors such as dirt, water and chemicals.

PVC (Polyvinyl Chloride) sheath

- Advantage:

Cheapest price among the three materials.

Easy to install and repair.

Good fire resistance.

Resistant to mild chemicals. - Defect:

Low mechanical strength.

Low heat resistance.

Vulnerable to aging over time.

Not environmentally friendly.

XLPE (Cross-Linked Polyethylene) sheath

- Advantage:

High mechanical strength.

Good heat resistance.

Good fire resistance.

Withstands strong chemicals.

Long lifespan. - Defect:

Cost is higher than PVC.

More difficult to install and repair than PVC.

Not environmentally friendly.

EPDM (Ethylene Propylene Diene Monomer) Sheath

- Advantage:

Best heat resistance and ozone resistance.

Withstands strong chemicals.

Good anti-aging.

Long lifespan.

Environmental friendliness. - Defect:

Highest cost among the three materials.

More difficult to install and repair than PVC and XLPE.

In addition, Solid Busbar can have a number of other parts such as:

- Connecting bar: Used to connect bus bars together.

- Bracket: Used to fix the busbar on the frame or rack.

- Other accessories: Such as bolts, screws, washers, etc.

The specific structure of Solid Busbar will depend on specific needs and applications.

3. Classification of Solid Busbar

Solid Busbar can be classified according to many different criteria, including:

3.1. Classified by shape:

- Flat busbar: This type of busbar has a flat shape, often used in electrical systems with limited installation space.

- Tube busbar: This type of busbar has a hollow tube shape, often used in electrical systems that require high load capacity.

- U-shaped busbar: This type of busbar is U-shaped, often used in outdoor electrical systems.

3.2. Classified by material

- Solid Copper Busbar

- Solid Aluminium Busbar

4. Advantage of Solid Busbar

Compared to traditional electrical cables, Solid Busbar possesses many advantages, bringing efficiency and safety to the electrical system:

- High electrical conductivity: Made from good conductive metals such as copper or aluminum, Solid Busbar has higher electrical conductivity than electric cables, helping to minimize power loss during transmission.

- High load capacity: Solid Busbar’s solid structure and good heat resistance allow the busbar to withstand large currents, meeting the power supply needs of large and complex electrical systems.

- High mechanical durability: Solid Busbar is made from metal materials with high mechanical durability, good impact and vibration resistance, ensuring stable operation in harsh environments.

- Easy installation and maintenance: Simple structure, Solid Busbar is easy to install and maintain, helping to save time and operating costs.

- Good fire resistance: Some types of Solid Busbar are designed with a fireproof cover, helping to prevent the spread of fire in case of fire, ensuring the safety of the electrical system.

- Good fire resistance: Some types of Solid Busbar are designed with a fireproof cover, helping to prevent the spread of fire in case of fire, ensuring the safety of the electrical system.

- High adaptability: Solid Busbar can be manufactured in many different shapes, sizes and materials, meeting the diverse needs of electrical systems.

- Save space: Compared to traditional electrical cable systems, Solid Busbar has a more compact size, helping to save installation space.

- Long life: With high mechanical strength and good corrosion resistance, Solid Busbar has a long life, helping to minimize replacement and maintenance costs.

- Environmentally friendly: Solid Busbar can be recycled, contributing to environmental protection.

- Safe to use: Solid structure and insulated cover make Solid Busbar safe to use, minimizing the risk of electric leakage and fire.

5. Application of Solid Busbar

Thanks to its outstanding advantages, Solid Busbar is widely used in many different fields, including:

- Factory electrical system: Distributes electricity from the main supply to equipment and machinery in the factory.

- High voltage power system: Transmission of power from power plant to transformer station.

- Underground electricity system: Supplying electricity to buildings, residential areas, and industrial zones.

- Other industrial applications: Subway power systems, elevators, trams, etc.

6. Some notes when using Solid Busbar

To ensure safety and effectiveness when using Solid Busbar, the following points should be noted:

- Choose the appropriate type of busbar: It is necessary to choose a type of busbar with size, material and load-bearing capacity appropriate to usage needs and operating conditions.

- Busbar system design: The busbar system needs to be designed to ensure safety, efficiency and meet technical requirements.

- Installation and maintenance: Busbar installation and maintenance should be performed by qualified personnel, in accordance with the manufacturer’s instructions.

7. Conclusion

Solid Busbar is an important component in the electrical system, playing the role of guiding the flow of power from the supply source to the loads. With outstanding advantages in electrical conductivity, load-bearing, mechanical durability and ease of installation, Solid Busbar is widely used in many different fields. Choosing and using the appropriate Solid Busbar will contribute to ensuring safety, efficiency and cost savings for the electrical system.

Why choose SHOGO Viet Nam?

1. Quality Commitment: SHOGO Viet Nam.,JSC is the No. 1 Busbar and Cable manufacturer in Viet Nam for the new energy industry. We are committed to providing our customers with products of the highest quality standards. All raw materials are inspected for quality before production, and 100% of products are thoroughly inspected before delivery. SHOGO Viet Nam holds prestigious certificates: IATF16949-2016, ISO 9001-2015, ISO 14001-2015, ISO/IEC 17025-2017,…

2. Competitive Pricing: With a team of experienced engineers who have participated in many electric vehicle production projects, SHOGO Viet Nam can provide product consulting to help customers optimize production costs and improve product quality. With a geographical location that is convenient for trading, along with modern machinery and technology, SHOGO Viet Nam can provide products at the most competitive prices on the market.

3. Dedicated Service: With a team of experienced employees, large production capacity and reasonable supply, SHOGO Viet Nam always ensures on-time delivery for customers. Support customers in all projects, quickly handle arising problems.

You can refer to some of our Busbar products on the page “PRODUCTS“.

To receive FREE CONSULTATION on our products, Busbar design and manufacturing services, please CONTACT

Email: info@shogovn.com / info@shogobusbar.com

Whatsapp / Wechat / Zalo : +84 989538022/ +84 393929885