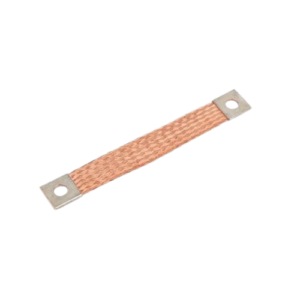

In the electrical system, the busbar plays an extremely important role as the main path to transmit power from the source to the consuming devices. Currently, there are two most popular types of bus bars on the market: braided copper bus bars and braided aluminum bus bars. Each type has its own advantages and disadvantages, suitable for different needs. This article will provide you with detailed information about these two types of busbars, including conductivity, weight, cost, durability, applications and selection considerations to help you make a decision. the most intelligent for your electrical system.

1. Electrical conductivity:

- Braided copper busbar:

Copper is a metal with higher electrical conductivity than aluminum (about 60%). Therefore, braided copper busbars are capable of conducting larger currents with lower power loss than braided aluminum busbars of the same size. Thanks to that, braided copper busbars help save energy and reduce the cost of operating the electrical system.

- Braided aluminum busbar:

Aluminum is lighter in weight than copper, resulting in a larger cross-section for the same weight. However, the lower conductivity of aluminum results in higher power loss compared to stranded copper busbars. Therefore, braided aluminum busbars are often used in cases where cost savings or light weight are required.

2. Weight:

- Braided copper busbar:

Copper is heavier than aluminum. Therefore, braided copper busbars are significantly heavier than braided aluminum busbars of the same size. This should be considered when selecting and installing, especially on systems with support structures that cannot withstand large loads.

- Braided aluminum busbar:

Aluminum is lighter in weight than copper, reducing the load on the support system and making it easier to install. This advantage is especially important for high-altitude construction projects or places with limited area.

3. Expense:

- Braided copper busbar:

Copper has a higher cost than aluminum. Therefore, braided copper busbars often cost more than braided aluminum busbars of the same size. The initial investment cost for a system using braided copper busbars will be higher than a system using braided aluminum busbars.

- Braided aluminum busbar:

Aluminum is cheaper than copper, helping to save initial costs for the electrical system. However, it should be noted that the higher power loss of braided aluminum busbars can result in higher operating costs over the life of the system.

4. Reliability:

- Braided copper busbar:

Copper has high strength and good corrosion resistance. Braided copper busbars have a longer lifespan than braided aluminum busbars in harsh environments, and are less susceptible to oxidation and rust over time.

- Braided aluminum busbars:

Aluminum is more susceptible to corrosion than copper, especially in environments with high humidity or exposure to chemicals. Braided aluminum busbars need to be protected from corrosive agents to ensure longevity and performance.

5. Application:

Braided copper busbar: Suitable for applications requiring large current, low power loss and high durability such as:

- Power plant

- Transformer station

- High-rise buildings

- Subway system

- Places with harsh environments and high humidity

Braided aluminum busbar: Suitable for applications requiring light weight, low cost and corrosion resistance in relatively dry environments such as:

- Solar power system

- Low voltage distribution system

- Electrical control cabinet

- Where space is limited, costs need to be saved

| Feature | Braided Copper Busbar | Braided Aluminum Busbar |

| Conductivity | High | Low |

| Weight | Heavy | Light |

| Cost | High | Low |

| Durability | High | Low |

| Heat Resistance | High | Low |

| Machinability | Easy | More difficult |

| Recyclability | High | High |

| Aesthetics | Golden | Silvery |

6. Factors to consider when choosing:

Choosing between braided copper busbars and braided aluminum busbars depends on many factors such as:

- Current: If your system needs to conduct large currents, stranded copper busbars are a better choice.

- Environment: If the system operates in harsh environments, braided copper busbars are more durable.

- Weight: If you need to save weight, braided aluminum busbars are the right choice.

- Cost: If your budget is limited, braided aluminum busbars are cheaper.

- Aesthetics: If you care about aesthetics, the braided copper busbar has a more luxurious golden color.

7. Notes when choosing and using:

- Consult an electrical expert before choosing the right type of busbar for your electrical system.

- Choose a reputable supplier to ensure product quality.

- Comply with electrical safety standards when installing and using busbars.

- Store the busbar in a cool, dry place, avoiding contact with chemicals and corrosive agents.

8. Conclusion:

Hopefully this article has provided you with detailed information about braided copper busbars and braided aluminum busbars so that you can make the most suitable choice for your electrical system. Carefully consider factors such as current, environment, weight, cost and aesthetics before making a decision.

Why choose SHOGO Viet Nam?

1. Quality Commitment: SHOGO Viet Nam.,JSC is the No. 1 Busbar and Cable manufacturer in Viet Nam for the new energy industry. We are committed to providing our customers with products of the highest quality standards. All raw materials are inspected for quality before production, and 100% of products are thoroughly inspected before delivery. SHOGO Viet Nam holds prestigious certificates: IATF16949-2016, ISO 9001-2015, ISO 14001-2015, ISO/IEC 17025-2017,…

2. Competitive Pricing: With a team of experienced engineers who have participated in many electric vehicle production projects, SHOGO Viet Nam can provide product consulting to help customers optimize production costs and improve product quality. With a geographical location that is convenient for trading, along with modern machinery and technology, SHOGO Viet Nam can provide products at the most competitive prices on the market.

3. Dedicated Service: With a team of experienced employees, large production capacity and reasonable supply, SHOGO Viet Nam always ensures on-time delivery for customers. Support customers in all projects, quickly handle arising problems.

You can refer to some of our Busbar products on the page “PRODUCTS“.

To receive FREE CONSULTATION on our products, Busbar design and manufacturing services, please CONTACT

Email: info@shogovn.com / info@shogobusbar.com

Whatsapp / Wechat / Zalo : +84 989538022/ +84 393929885