Electric cables play an important role in transmitting electricity, and are classified into many different types based on operating voltage. The two most common types of cables are HV cables (high voltage cables) and LV cables (low voltage cables). Clearly distinguishing these two types of cables is essential to ensure safety and efficiency in the electrical system.

This article will provide you with detailed information about the differences between HV cable and LV cable, including:

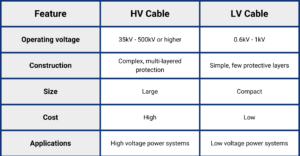

1. Operating voltage:

- HV Cable: Designed to operate at high voltages, typically from 35kV to 500kV or higher.

- LV Cable: Designed to operate at low voltages, typically from 0.6kV to 1kV.

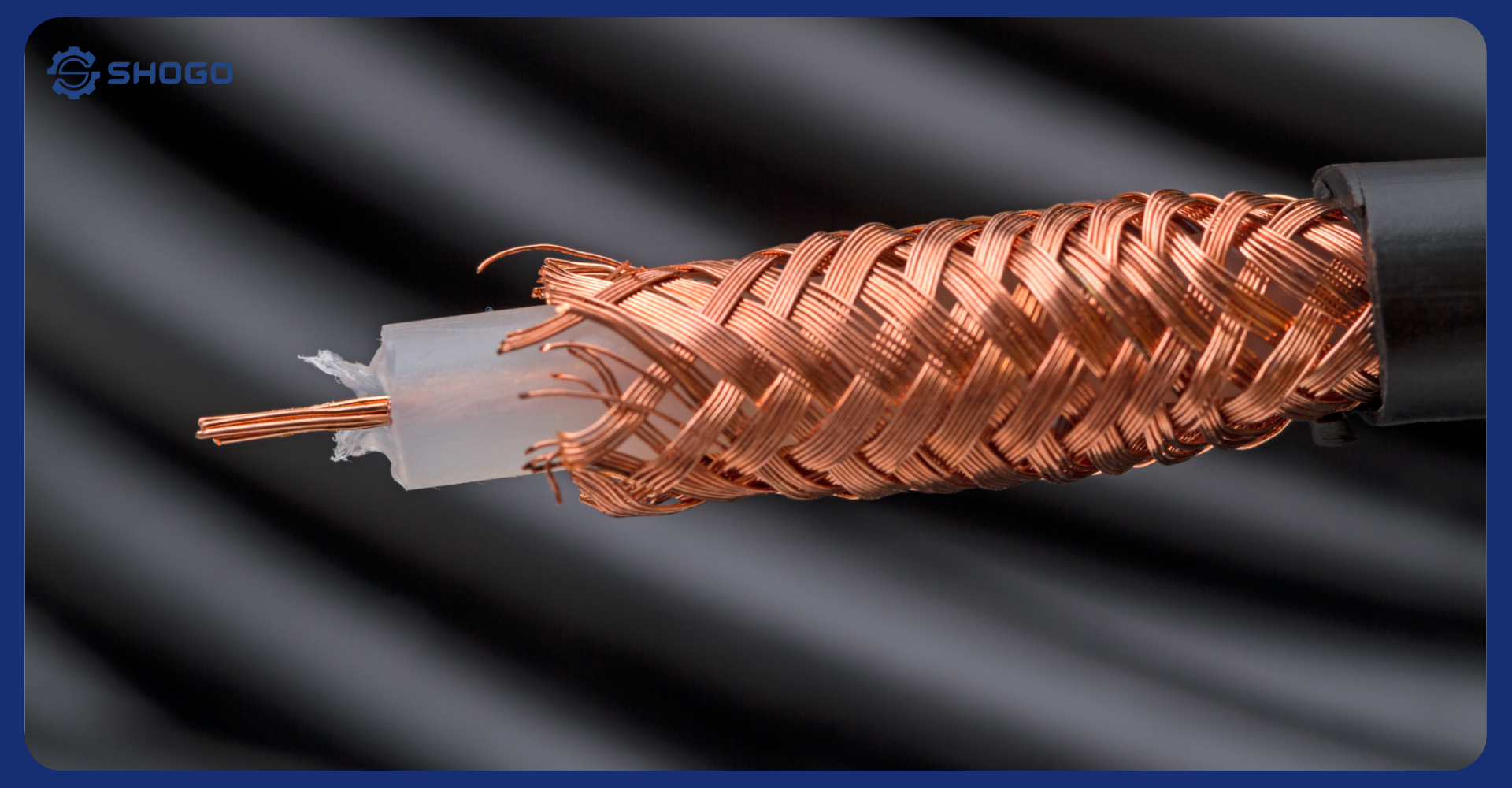

2. Structure:

HV cable: Due to high voltage, HV cable has a more complex structure than LV cable. The structure of HV cables often includes many layers, including:

- Conductor core: Made of copper or aluminum, responsible for conducting electricity.

- Insulating layer: Made of insulating material with high electrical strength such as XLPE (cross-linked polyethylene), EPR (ethylene propylene rubber), or tar paper.

- Semiconducting layer: Helps evenly distribute the electric field in the insulation layer and minimize electrical discharge in the cable.

- Shielding layer: Protects the cable from the impact of external electric and magnetic fields.

- Shell: Protects the cable from the effects of the external environment.

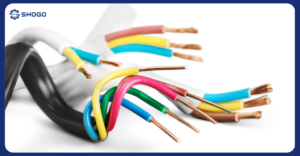

LV cable: Structure is simpler than HV cable, including:

- Conductor core: Usually made of copper or aluminum.

- Insulation layer: Made of PVC (polyvinyl chloride), XLPE or EPR.

- Sheath: Protects the cable from the environment.

3. Size:

- HV cable: Due to many layers of protection and the need to conduct electricity with high intensity, HV cables are often larger in size than LV cables.

- LV cable: Compact size than HV cable, helping to save installation space.

4. Price:

- HV cable: Higher production costs due to complex structure and high-quality materials used.

- LV cable: Cheaper price than HV cable.

5. Application:

HV cable: Used in high voltage electrical systems such as:

- Power transmission system: Transmitting power from the power plant to auxiliary transformer stations.

- Power distribution system: Distributes power from sub-transformer stations to power consumers.

- High voltage direct current (HVDC) power system: Transmits direct current power over long distances.

LV cable: Widely used in low voltage electrical systems such as:

- Supplying electricity to buildings, houses, and residential areas.

- Supplying electricity for industrial electrical equipment.

- Provide electricity for the lighting system.

6. Note:

Choosing the right cable type depends on many factors such as system voltage, transmission capacity, environmental conditions and budget. It is necessary to comply with technical standards and safety regulations when installing and using HV cables and LV cables.

Hope this article has provided you with complete and detailed information about the difference between HV cable and LV cable. Understanding the characteristics and applications of each type of cable will help you choose the appropriate cable for your electrical system, ensuring safety and efficiency during use.

Why choose SHOGO Viet Nam?

1. Quality Commitment: SHOGO Viet Nam.,JSC is the No. 1 Busbar and HV Cable manufacturer in Viet Nam for the new energy industry. We are committed to providing our customers with products of the highest quality standards. All raw materials are inspected for quality before production, and 100% of products are thoroughly inspected before delivery. SHOGO Viet Nam holds prestigious certificates: IATF16949-2016, ISO 9001-2015, ISO 14001-2015, ISO/IEC 17025-2017,…

2. Competitive Pricing: With a team of experienced engineers who have participated in many electric vehicle production projects, SHOGO Viet Nam can provide product consulting to help customers optimize production costs and improve product quality. With a geographical location that is convenient for trading, along with modern machinery and technology, SHOGO Viet Nam can provide products at the most competitive prices on the market.

3. Dedicated Service: With a team of experienced employees, large production capacity and reasonable supply, SHOGO Viet Nam always ensures on-time delivery for customers. Support customers in all projects, quickly handle arising problems.

You can refer to some of our Busbar products on the page “PRODUCTS“.

To receive FREE CONSULTATION on our products, Busbar design and manufacturing services, please CONTACT

Email: info@shogovn.com / info@shogobusbar.com

Whatsapp / Wechat / Zalo : +84 989538022/ +84 393929885