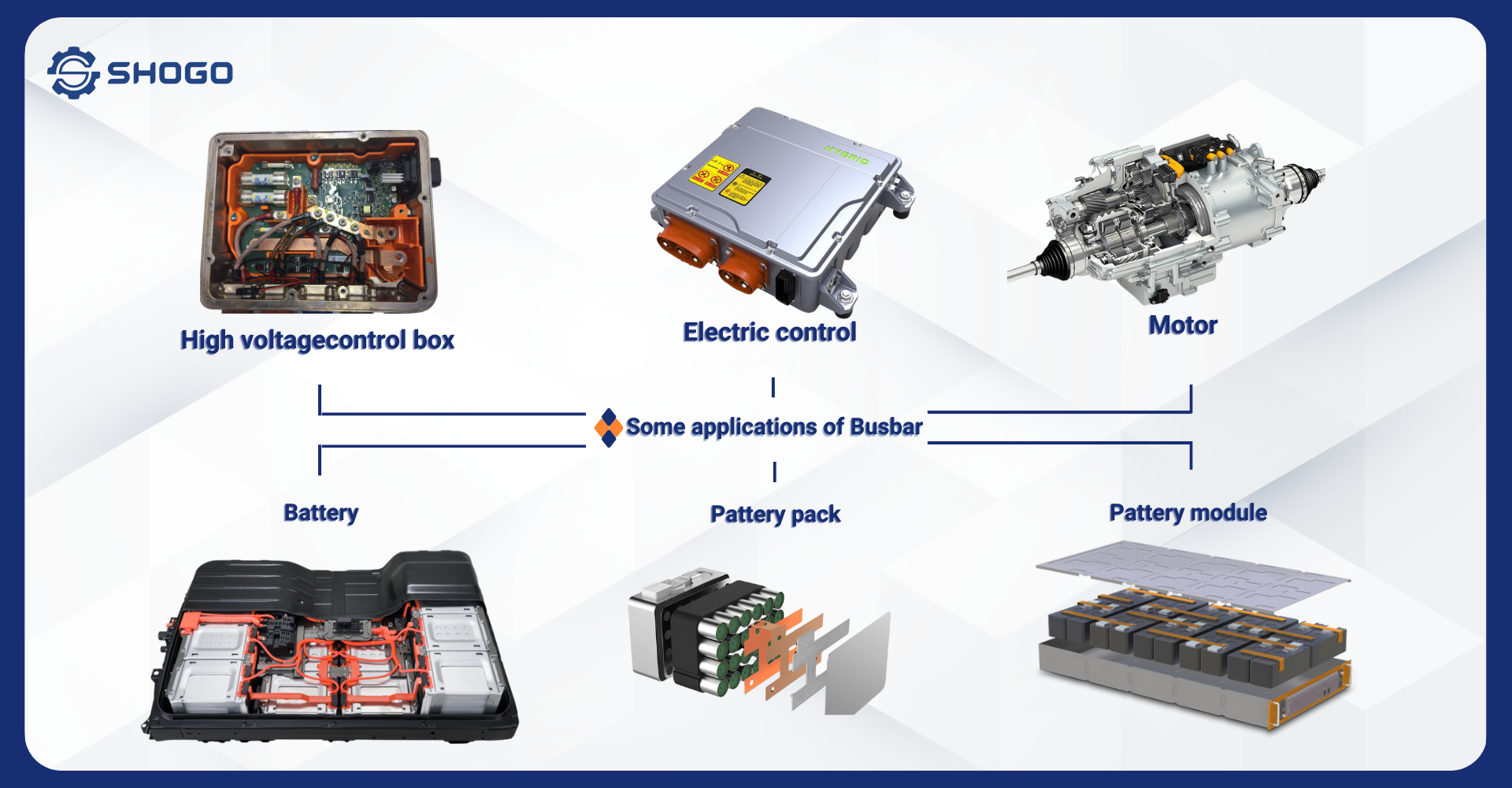

Busbars play a crucial role in electric vehicle (EV) battery systems, directly impacting the vehicle’s performance, durability, and safety. Selecting the right busbars is essential to ensure optimal EV operation and safety. This article will delve into the key considerations when choosing busbars for EV battery systems:

1. Material:

The choice of busbar material depends on several factors, including:

- Conductivity: Higher conductivity minimizes electrical energy losses. Copper offers the highest conductivity, followed by aluminum and tin-plated copper.

- Current Carrying Capacity: Busbars must withstand high currents during EV operation. Copper has the best current carrying capacity, followed by aluminum and tin-plated copper.

- Weight: Lighter busbars reduce overall vehicle weight, contributing to increased range. Aluminum is the lightest, followed by tin-plated copper and copper.

- Cost: Copper is generally more expensive than aluminum. Tin-plated copper falls in the middle range.

- Corrosion Resistance: Busbars need good corrosion resistance for long-term durability in harsh environments. Aluminum offers better corrosion resistance than copper. Tin-plated copper has comparable corrosion resistance to copper.

2. Size:

Busbar size depends on the current passing through it. The busbar’s cross-sectional area must be large enough to carry the current without overheating. Use the following formula to calculate the minimum busbar cross-section:

S = I^2 / (ρ * j)

Where:

- S: Busbar cross-sectional area (mm²)

- I: Current (A)

- ρ: Resistivity of busbar material (Ωm)

- j: Allowable current density (A/mm²)

The allowable current density depends on the busbar material and operating conditions. Refer to the busbar supplier’s technical documentation for the appropriate current density value.

3. Shape:

Busbars come in various shapes, including:

- Flat bars: Easy to manufacture, install, and cost-effective.

- Round bars: Offer better conductivity than flat bars but are more challenging to manufacture and install.

- Grooved bars: Combine the advantages of flat and round bars, providing good conductivity, ease of manufacture, and installation.

The choice of busbar shape depends on the battery system design and busbar installation method.

4. Connectivity:

Busbars must have good connectivity with battery cells and other components in the battery system. Common connection methods include:

- Welding: Provides a strong and secure connection but is difficult and time-consuming to implement.

- Crimping: Offers a fast and easy connection but may not be as durable as welding.

- Clamping: The simplest connection method but not as secure as welding or crimping.

The choice of connection method depends on the requirements for durability, performance, and cost.

5. Heat Resistance:

Busbars must withstand high temperatures during EV operation. Choose busbars made from materials with good heat resistance and a design that promotes efficient heat dissipation.

6. Safety:

Busbars must be designed and manufactured according to safety standards to ensure the safety of users and the EV. Common safety standards for EV busbars include:

- UL 946

- IEC 60851

- GB/T 18384

Select busbars that comply with the appropriate safety standards for the EV’s usage region.

7. Supplier:

You should choose busbar from a reputable supplier to ensure quality and reliability. A reputable supplier should have:

- Experience in manufacturing busbars for electric vehicles

- Good quality management system

- International certificate for electric vehicle busbar

- Good customer service

8. Some other notes:

- You should choose a busbar with a smooth surface, without burrs or burrs to avoid damaging the battery cell or other parts in the battery system.

- Busbar needs to be installed properly to ensure safety and operational efficiency.

- The busbar should be checked periodically to ensure proper operation and replaced when necessary.

Choosing the right busbar for an electric vehicle battery system is extremely important to ensure performance, durability and safety of the electric vehicle. This article has shared in detail what to keep in mind when choosing a busbar. Hope this information will be useful to you.

Why choose SHOGO Viet Nam?

1. Quality Commitment: SHOGO Viet Nam.,JSC is the No.1 Busbar and Cable manufacturer in Viet Nam for the new energy industry. We are committed to providing our customers with products of the highest quality standards. All raw materials are inspected for quality before production, and 100% of products are thoroughly inspected before delivery. SHOGO Viet Nam holds prestigious certificates: IATF16949-2016, ISO 9001-2015, ISO 14001-2015, ISO/IEC 17025-2017,…

2. Competitive Pricing: With a team of experienced engineers who have participated in many electric vehicle production projects, SHOGO Viet Nam can provide product consulting to help customers optimize production costs and improve product quality. With a geographical location that is convenient for trading, along with modern machinery and technology, SHOGO Viet Nam can provide products at the most competitive prices on the market.

3. Dedicated Service: With a team of experienced employees, large production capacity and reasonable supply, SHOGO Viet Nam always ensures on-time delivery for customers. Support customers in all projects, quickly handle arising problems.

You can refer to some of our Busbar products on the page PRODUCTS

To receive FREE CONSULTATION on our products, Busbar design and manufacturing services, please CONTACT

Email: info@shogovn.com / info@shogobusbar.com

Whatsapp / Wechat / Zalo : +84 989538022 / +84 393929885