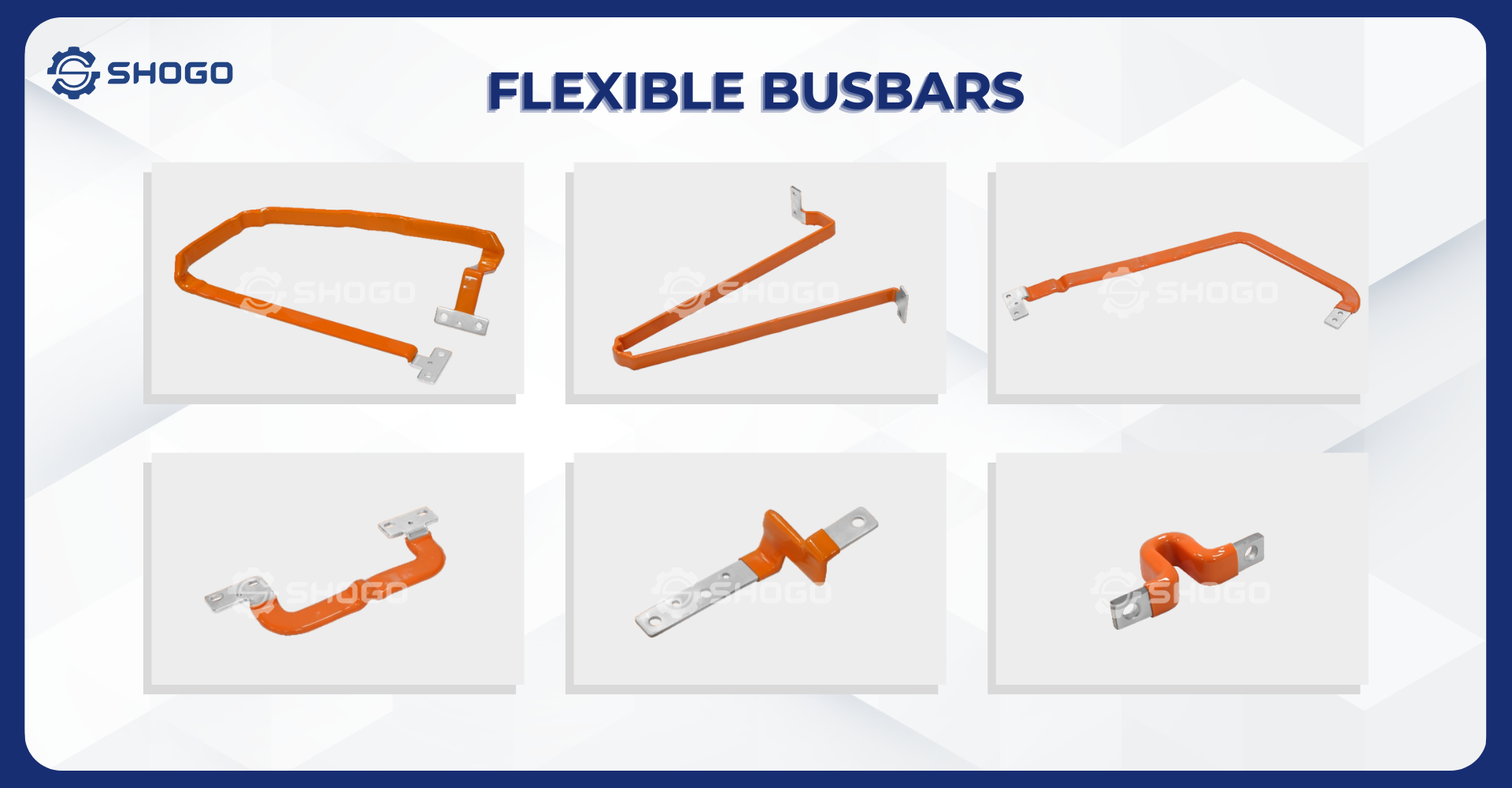

Flexible Busbar is a step forward in the field of conduction. With its unique structure, Flexible Busbar brings high flexibility and great adaptability to electrical systems.

This article will delve into the structure, classification and outstanding advantages of Flexible Busbar compared to traditional Busbars, and introduce the diverse applications of this product in practice.

1. What is Flexible Busbar?

Flexible busbar is made of multiple layers of copper or aluminum foil stacked on top of each other, each layer has a thickness of 0.1 to 1mm. They are manufactured by welding, stamping, plating, forming, insulation, etc. The plating can be tin and nickel.

2. Structure of Flexible Busbar

Flexible Busbar is made up of many layers of materials, in general the structure of the product will include the following parts:

2.1. Conductive core

- Is the most important part of Flexible Busbar, responsible for conducting electricity.

- Made from multiple layers of copper or aluminum stacked on top of each other

- The number of layers and cross-section of each layer will determine the electrical conductivity of the Flexible Busbar.

2.2. Protective shell

- Responsible for protecting Flexible Busbar from environmental impacts such as dirt, water, chemicals and protecting users from the risk of electric shock and electric leakage.

- Common protective cover materials are PVC, XLPE, EPDM,…

- The thickness of the protective layer depends on the voltage used by the Flexible Busbar.

2.3. Accessory

- Cosse, connector, mounting bar,… help connect Flexible Busbar with other electrical equipment.

- Accessory material is usually copper or aluminum, plated with tin or nickel to prevent corrosion.

2.4. In addition, Flexible Busbar can have additional layers such as

- Fireproof layer: Helps limit the spread of fire in case of fire.

- Anti-electromagnetic interference layer: Helps minimize the effects of electromagnetic interference on other electrical devices.

3. Classification of Flexible Busbar

Flexible Busbar is divided into many types depending on material and purpose of use.

In general, Flexible Busbar will be divided into 2 main types according to material:

-

Flexible Copper Busbar

-

Flexible Aluminium Busbar

4. Features of Flexible Busbar

4.1. Conducts and distributes electricity

Flexible Busbar helps transmit and distribute power from the power source to electrical equipment effectively. Busbars can be used to distribute power to various electrical devices in an electrical system. Busbar is often used to connect solar panels together in solar farms, wind turbine systems, hydropower, and geothermal.

4.2. Connect the electrical system

Flexible Busbar is used to connect electrical equipment and electrical components together. Flexible Busbar makes connecting devices easier and more flexible while still providing good electrical conductivity.

5. Advantage of Flexible Busbar

- Flexible, easy to install: Flexible busbars can be bent and shaped easily, can be installed by many different methods, including clamps, screws,… helping to install in spaces Being cramped becomes easier.

- Ability to withstand high current: Due to its special structure, Flexible Busbar can withstand higher current than traditional electric cables.

- Vibration handling: Flexible Busbar is used to reduce vibration in electrical systems with high vibration, such as factories, plants, etc.

- Thermal expansion compensation: Flexible Busbar can compensate for thermal expansion due to temperature changes, helping the electrical system operate more stably and safely.

- Lightning protection: Flexible Busbar can be used to conduct electricity from lightning to ground, helping to protect buildings from damage caused by lightning strikes.

- Fire and corrosion resistance: Flexible Busbar is made from many layers of copper or aluminum so it has very good vibration resistance, and the protective layer will help prevent fire and corrosion. This will make them suitable for products used in harsh weather.

6. Application of Flexible Busbar

6.1. Connect the high voltage power source

Flexible Busbar is used to connect transformers, generators, disconnectors, etc. with hard busbar system. Thanks to its good vibration resistance, Flexible Busbar helps protect equipment from damage caused by vibration during operation.

6.2. Connect the grounding system

Flexible Busbar is used to connect devices to the grounding system, helping to ensure safety for users and equipment.

6.3. Other applications

- Cable ladder system: Flexible Busbar is used to connect busbars in the cable ladder system.

- Electrical cabinet: Flexible Busbar is used to connect devices in the electrical cabinet.

- Industrial machinery: Flexible Busbar is used to connect electrical components in industrial machinery

7. Conclusion

Flexible Busbar is a flexible and efficient solution for electrical systems, providing many outstanding benefits compared to traditional busbars. Thanks to its flexibility, high electrical conductivity, durability and ease of installation, Flexible Busbar is increasingly widely used in many different fields

Why choose SHOGO Vietnam?

1. Quality Commitment: SHOGO Vietnam.,JSC is the No. 1 Busbar and Cable manufacturer in Vietnam for the new energy industry. We are committed to providing our customers with products of the highest quality standards. All raw materials are inspected for quality before production, and 100% of products are thoroughly inspected before delivery. SHOGO Vietnam holds prestigious certificates: IATF16949-2016, ISO 9001-2015, ISO 14001-2015, ISO/IEC 17025-2017,…

2. Competitive Pricing: With a team of experienced engineers who have participated in many electric vehicle production projects, SHOGO Vietnam can provide product consulting to help customers optimize production costs and improve product quality. With a geographical location that is convenient for trading, along with modern machinery and technology, SHOGO Vietnam can provide products at the most competitive prices on the market.

3. Dedicated Service: With a team of experienced employees, large production capacity and reasonable supply, SHOGO Vietnam always ensures on-time delivery for customers. Support customers in all projects, quickly handle arising problems.

You can refer to some of our Busbar products on the page “PRODUCTS“.

To receive FREE CONSULTATION on our products, Busbar design and manufacturing services, please CONTACT

Email: info@shogovn.com / info@shogobusbar.com

Whatsapp / Wechat / Zalo : +84 989538022/ +84 393929885