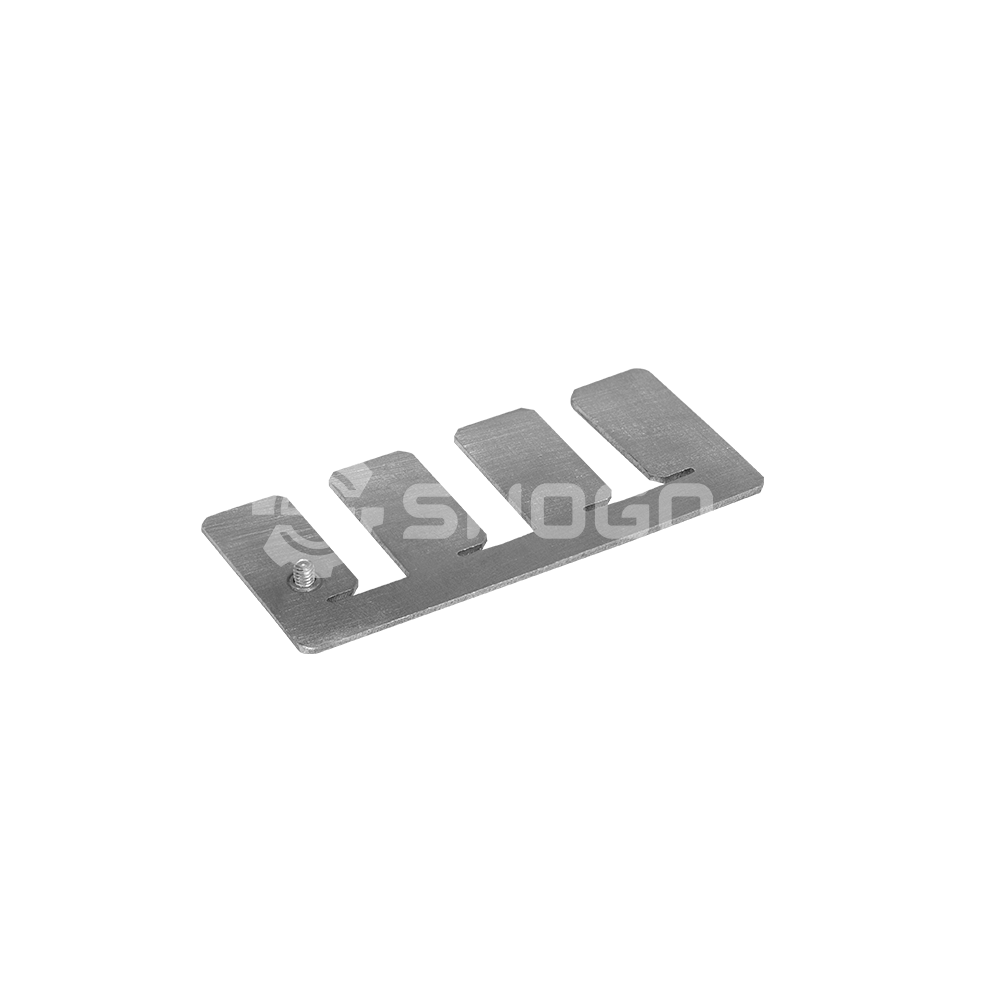

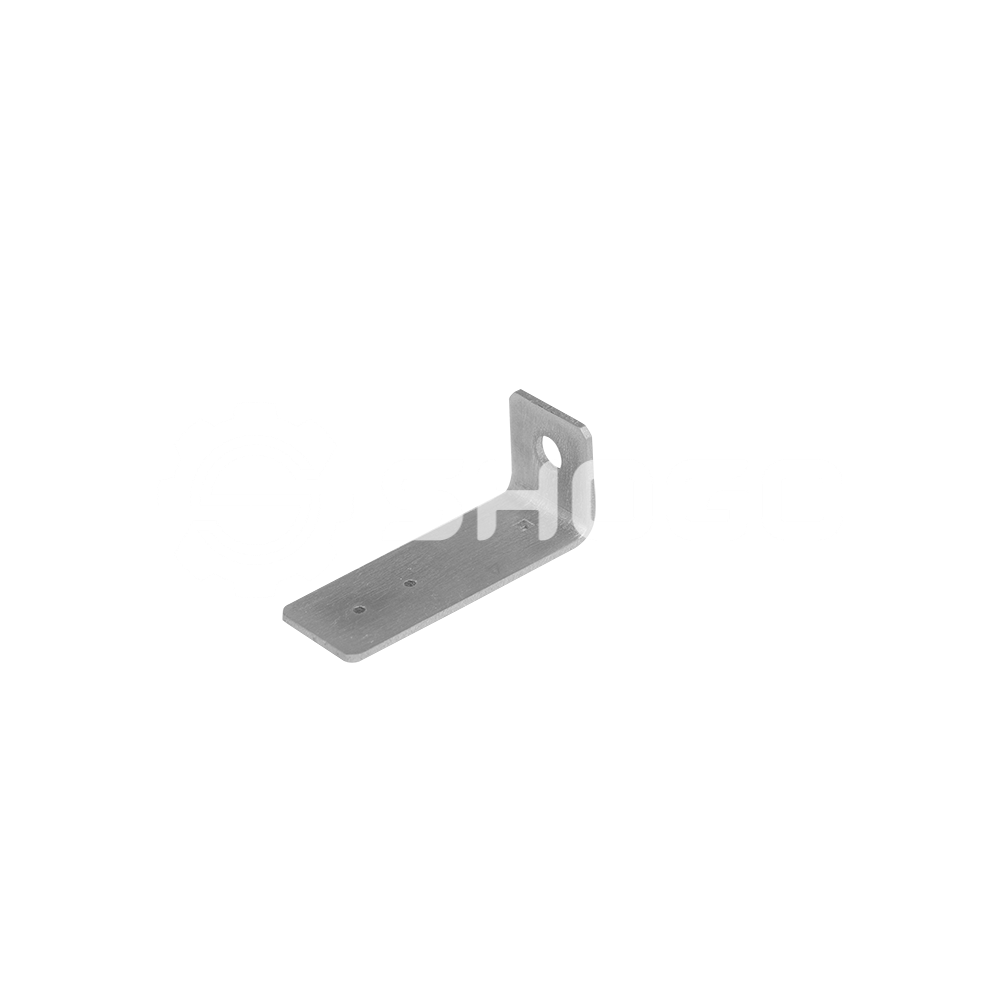

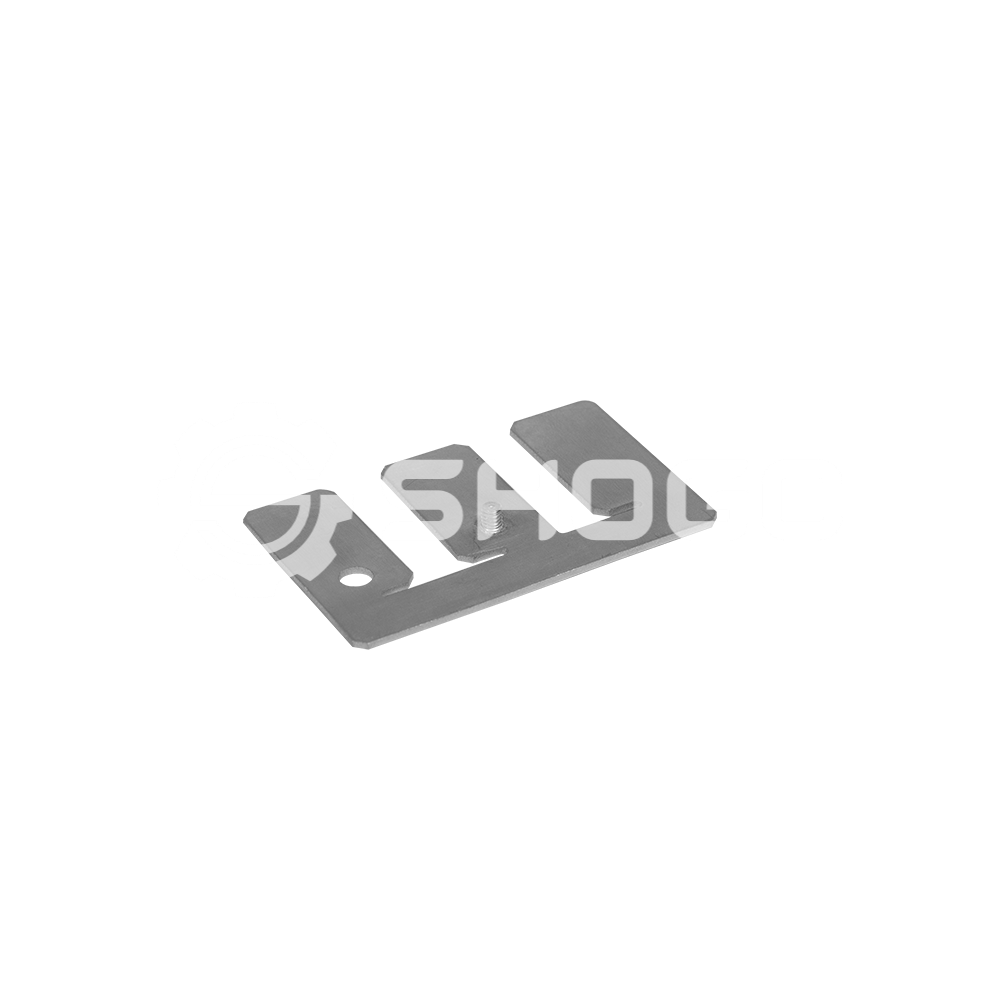

Aluminum busbar 0001

General Information

- Shape: Can be customized according to customer drawings

- Material: Aluminum / Optional material upon request

- Plating options: Tin plating / Nickel plating / Silver plating / Plating upon request

- Insulation and electrical insulation options: Heat shrinkable tube / PVC coating / Epoxy powder/ insulation tape / Insulation option upon request

- Certificate: ISO9001:2015; RoHS

Product Feature

Lightweight:

Aluminum busbars are approximately one-third the weight of copper busbars of the same size. This helps to reduce transportation and installation costs, as well as reduce the load on structures.

Flexible connectivity:

Aluminum busbars can be easily bent and shaped to fit into tight spaces. This makes them ideal for use in applications where space is limited.

Anticorrosion:

Aluminum busbars are made of corrosionresistant materials, which help to ensure the lifespan of electrical systems.

Advantage

Cost savings

Aluminum busbars are less expensive than copper busbars and are designed to be flexible. This makes them easier to install and reduces production costs.

Scalability

Aluminum busbars can be designed to be easily expandable. This can help meet future growth needs.

Improved performance & durability

Aluminum busbars can be designed to reduce power losses and increase resistance to harsh conditions. This can lead to improved performance and durability for the system

Application

We are specialized in copper and aluminium busbar that is applied in battery, energy storage system & electric vehicles.

Electric vehicles like hybrid battery car, electric golf car, electric logistic vehicle, electric bus, high-speed rail, electric forklift etc.

We supply directly to many battery pack companies and energy storage companies like solar energy household storage projects in UK, Americal, Australia etc. offering solutions for their battery connecting. They use both flexible and solid copper busbar to meet different design and application requirments.

Application

We are specialized in copper and aluminium busbar that is applied in battery, energy storage system & electric vehicles. Electric vehicles like hybrid battery car, electric golf car, electric logistic vehicle, electric bus, high-speed rail, electric forklift etc. We supply directly to many battery pack companies and energy storage companies like solar energy household storage projects in UK, Americal, Australia etc. offering solutions for their battery connecting. They use both flexible and solid copper busbar to meet different design and application requirments.